ASTM B117

What is the standard?

ASTM B117 salt spray (or salt fog) test is a standardized and popular corrosion test method, used to check corrosion resistance of materials and surface coatings, commonly applicable to metallic products. Salt spray testing is an accelerated corrosion test that produces a corrosive attack on our stainless steel accessories in order to evaluate the degree of protection against corrosion. The salt spray test is one of the most widespread and long established corrosion tests. ASTM B117 was the first internationally recognized salt spray standard, originally published in 1939. Other important relevant standards are ISO 9227, JIS Z 2371 and ASTM G85.

How is it tested?

Accessories , such as hinges and lifting hooks, which are fitted externally to our GRP enclosures that are exposed to the weather are subjected to a concentrated salt solution for a duration of 300 hours to simulate accelerated corrosion. Post, the appearance of corrosion characteristics (rust) the accessories are evaluated by determining signs of cracking, flacking, blistering or loss of adhesion.

Where is it tested?

The stainless accessories are tested at an independent testing laboratory validated to carry out examinations stipulated by ASTM standards. Passing the ASTM B117 salt spray test certifies our GRP enclosures in totality to be corrosion resistant and suitable to be installed in high salt content environments such as shoreline locations. Adherence to the standard is mandatory across the GCC region and global locations with shorelines. ASTM International is an international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, and services.

Enclosures

Enclosures Kiosks

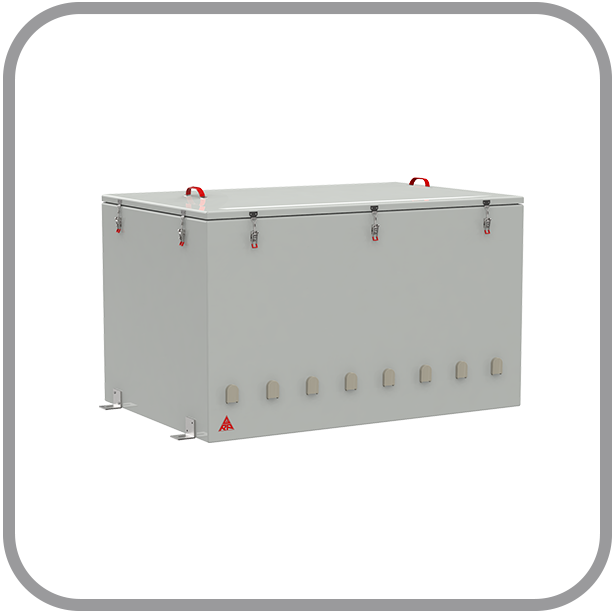

Kiosks Battery Enclosures

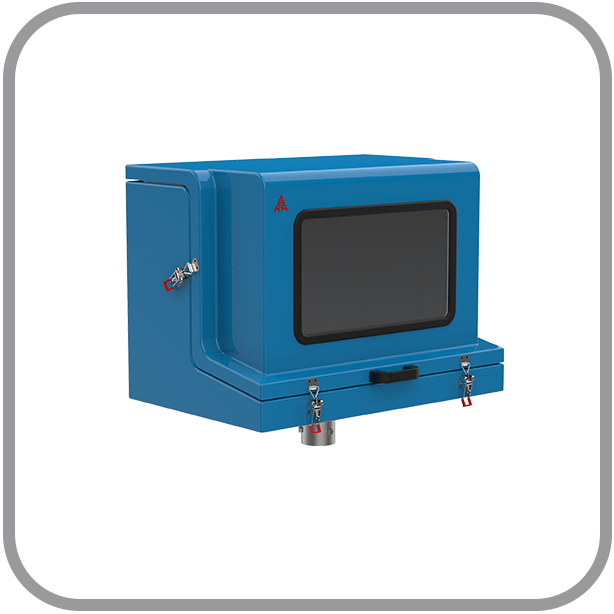

Battery Enclosures Instrumentation Products

Instrumentation Products Fire and Safety Enclosures

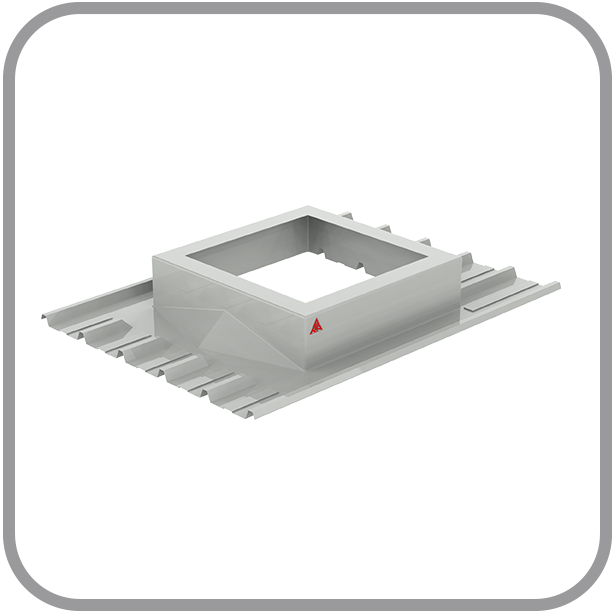

Fire and Safety Enclosures Roofing Systems Products

Roofing Systems Products Utility Approved Enclosures

Utility Approved Enclosures Customized Products

Customized Products