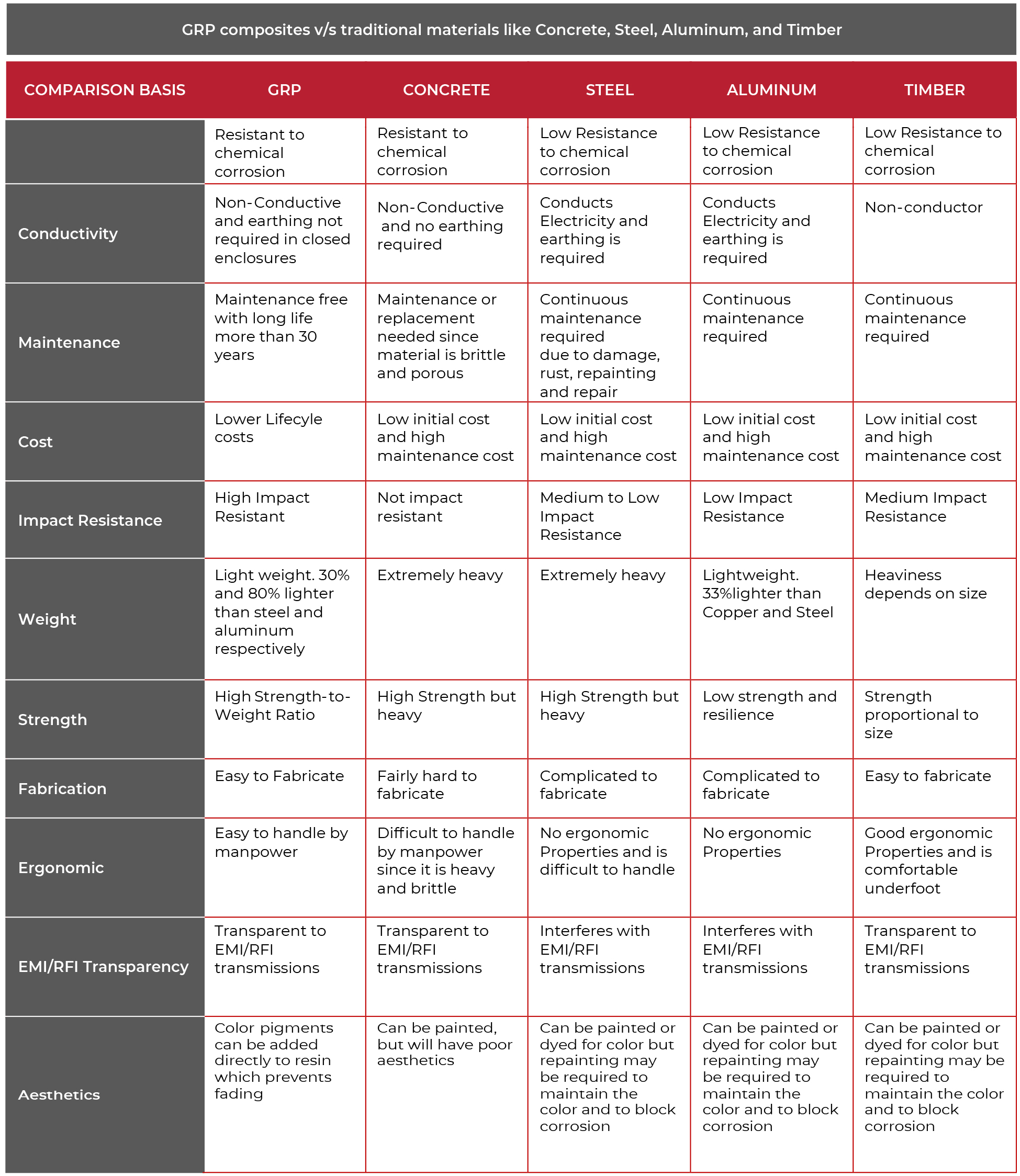

Fiber-reinforced composites offer excellent strength-to-weight ratios, exceeding those of other materials, making products easy to handle and install. This can save money and manpower on projects.

“GRP” Advantage

Glass Reinforced Polyester : a composite material consisting of glass fibers embedded in a synthetic polyester resin. The glass fibers usually take the form of strands, rovings, fabrics, mats, and chopped strands.

By combining specific resins and reinforcements, the strength of composite materials can be customized to meet requirements of any application. Composites exhibit high strength-to-weight ratio (also known as specific strength), tensile strength (comparative to steel), sheer strength (when torsional forces are subjected) and impact resistance (ability of a material to withstand a high force or shock applied to it over a short period of time).

Composites do not rust or corrode. Products made from composites provide longterm resistance to severe chemical and temperature environments; often the material choice for outdoor exposure. There are many examples of glass fiber reinforced polyester enclosures being in service for more than 25 years, operating in high temperature environments. Composites offer corrosion-resistant solutions for many industries, including oil & gas, water and wastewater treatment. Properly designed composites have a long service life and minimum maintenance.

How long do our products last? There is no easy answer. That’s because many of the first GRP enclosures put in place more than 25 years ago have not yet come to the end of their lives. Composites hold up well against fatigue and are resistant to environmental factors such as U.V. damage, temperature fluctuations, moisture, sand blasting effect and chemical exposure. They also require less scheduled and unexpected maintenance.

Composites pack a powerful one-two punch with their ability to be molded into complex shapes with precise properties and smooth surface appearance aesthetics. At a relatively low cost, composites are formed when the resin cures – or solidifies – during production easily taking on many shapes, whether they’re created in low volumes manually or manufactured using high-volume, automated processes.

Giant Reinforced Plastic Industries : the leading manufacturer since 1989 of industrial polyester products for the power, water, oil & gas, solar, telecom and construction sectors in the MENA region.

We recognize that our client’s time is valuable. Therefore we place a high emphasis on training our sales and marketing team to respond to our clients with proposals, technical details, production progress updates and delivery information within one business day. Its not only the “when” that matters but also the “what” - our communication to you is tailored to offer clarity, be concise; and transmit coherence, readability, ethics.

See our values

Our story began in 1989 and we have stayed true to our core competency of composites manufacturing for over 25 years. Today, our production team still consists of engineers and technicians that have been part of the team since inception. What does that mean? A lifetime’s wealth of knowledge manufacturing industrial composite products for the power distribution, water distribution and oil & gas sectors. When all is said and done, we are the experts.

See our history

Composite manufacturing requires large capital investments into moulds and their storage. Customarily, these mould costs are passed onto the customers. At GRP Industries, we have accumulated an inventory of thousands of moulds over our plus 25 years history. With that, our product range is so vast in size and specifications that we are sure to meet any client’s requirement at demand with zero mould costs passed on. If that doesn’t work, we can always manufacture any customized products with our in-house mould department.

See our products

We have established the infrastructure catered to smoothly deliver our products across the world. Our global offices in the Gulf region and the United States cater to our major markets, our strategic partnerships with our Distributors provide on the ground support to our mid-level markets; and our close proximity to the tradehub city of Dubai, United Arab Emirates ensures quick access to sea, air and ground transport of our products to any corner of the world.

See our major markets

Our hiring practice enforces that the people at GRP Industries hold certified Engineering Degrees to be a member of our Sales and Production teams. In addition to their education, our people go through an in-house training program and continuing education via external training centers in their respective employment. In all of this, the most important element in the recruitment process is their “character”. Our people are required to be cooperative, multi-tasking, efficient, friendly and be able to work in teams. What does this boil down to? Our promise that our representative is qualified and ready to assist our clients.

We believe in Quality throughout our system. That is why our Integrated Management System (IMS) captures the requirements of industry best practices, based on the three major standards which we work to; ISO 9001, ISO 14001 and OHSAS 18001. When it comes to our products, we put each of their features to the test by having them tested and certified to global standards by independent test labs in the United States and United Kingdom.

See our certifications

The company’s growing framework consists of three manufacturing facilities and corporate offices across the world, employing over 200 people. In addition is a distribution network with local distributors in the MENA and Asia Pacific regions. Our Goal - be where our clients are to provide them support year round.

See Our Locations

Due to all of the above reasons, GRP Industries has been collaborating and is the registered approved vendor with the power, water, sewerage, oil & gas and solar utility authorities in the Gulf region. Thus, our clients don't incur any issues in achieving approvals with our products.

See our Approvals

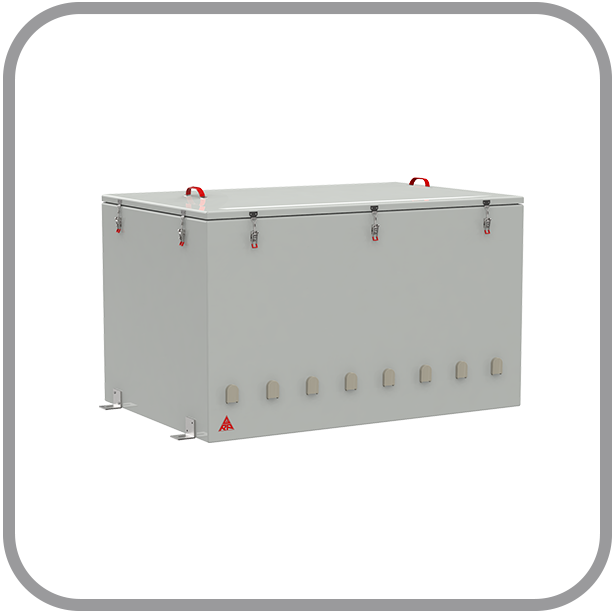

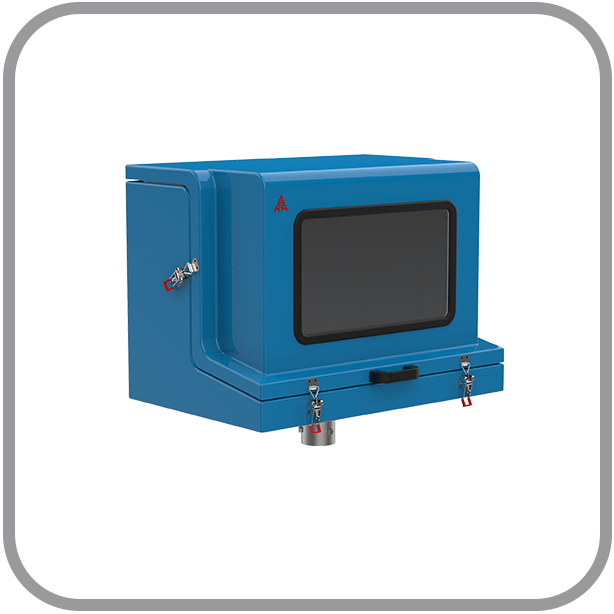

Enclosures

Enclosures Kiosks

Kiosks Battery Enclosures

Battery Enclosures Instrumentation Products

Instrumentation Products Fire and Safety Enclosures

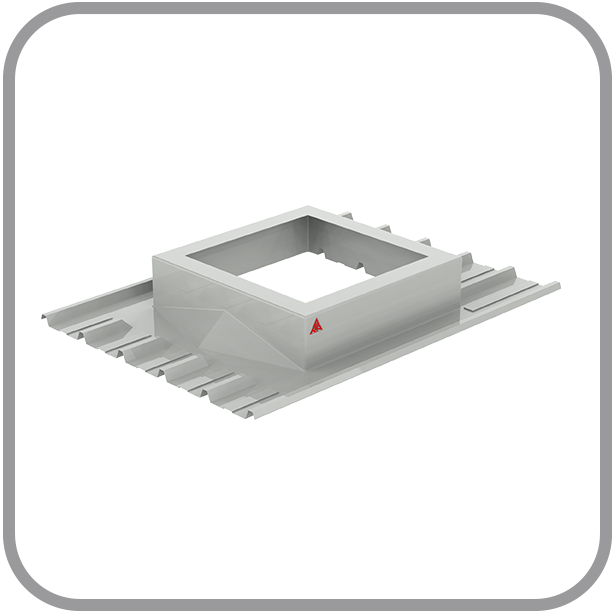

Fire and Safety Enclosures Roofing Systems Products

Roofing Systems Products Utility Approved Enclosures

Utility Approved Enclosures Customized Products

Customized Products