BS 2782-Part 10

What is the standard?

The British Standard BS 2782-Part 10 is described as the methodology of testing glass reinforced plastics. Relative to our glass reinforced polyester laminate, are the following physical and chemical parameters:

- Tensile Strength (METHOD 1003)

- Elongation (METHOD 1003)

- Flexural Strength (Method 1005)

- Impact Strength (Method 1005)

- Loss on ignition (Method 1002)

- Glass Content (Method 1002)

The overall purpose of the standard being to test the quality and strength of the glass reinforced plastic by providing quantitate data on the physical and chemical properties.

How is it tested?

Our glass reinforced polyester laminate, the primary material across our product range, is placed in a controlled atmospheric environment and then repeatedly subjected to loads in order to determine the tensile strength, elongation and flexural strength. Examination equipment record the results for each test and an average of the performance is recorded. Impact strength data is recorded by physically observing damage to the laminate upon drops of 1 Kg weight on the laminate. Loss on ignition data is recorded by testing equipment after a flame is applied to the laminate and then compared to a control specimen. Glass content of the laminate is electronically measured with the basis that higher glass content correlates to higher strength.

Where is it tested?

The GRP laminate is tested at an independent testing laboratory verified to carry out examinations stipulated by the BSI Group. The BSI Group produces British Standards under the authority of the Royal Charter in the United Kingdom, which states that one of BSI’s objectives is to create standards of quality for goods and services. GRP Industries practices different manufacturing processes for the production of its glass reinforced polyester laminate; hence we achieve different laminates varying in their physical and chemical characteristics. For example, our vacuum infusion laminate has a higher content of glass and therefore performs higher in strength than our contact molding laminate. GRP Industries carries out BS 2782-Part 10 Physical and Chemical Parameters testing on all forms of its laminate; as commonly requested globally.

Enclosures

Enclosures Kiosks

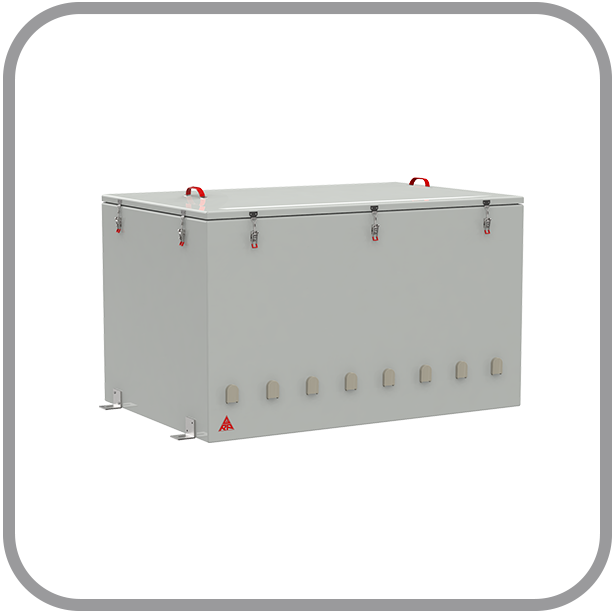

Kiosks Battery Enclosures

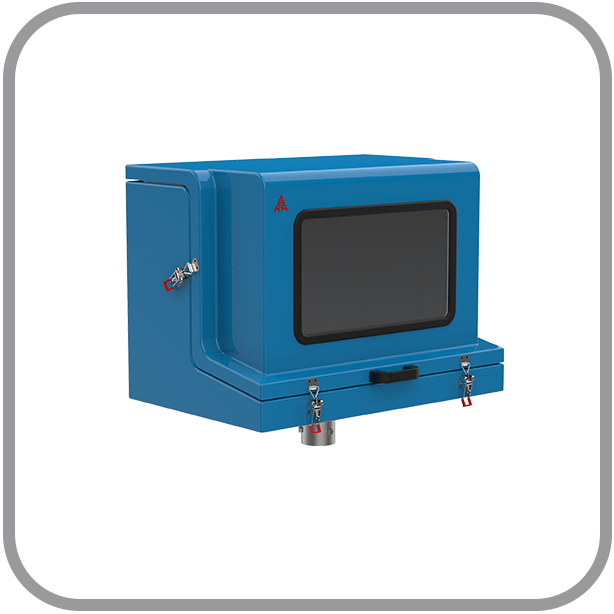

Battery Enclosures Instrumentation Products

Instrumentation Products Fire and Safety Enclosures

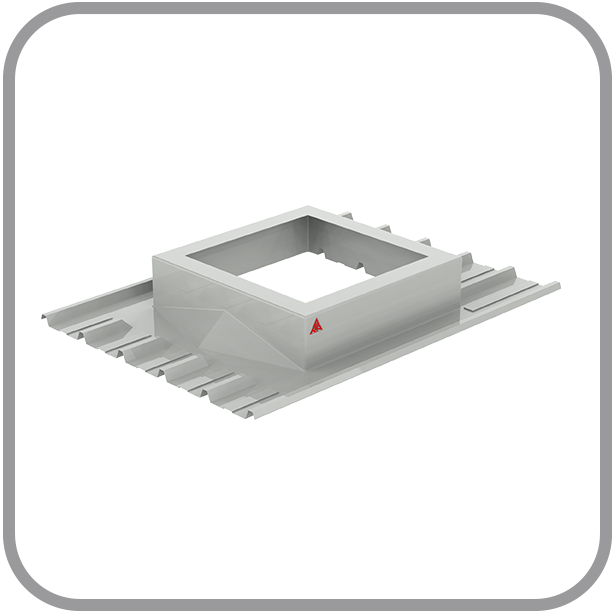

Fire and Safety Enclosures Roofing Systems Products

Roofing Systems Products Utility Approved Enclosures

Utility Approved Enclosures Customized Products

Customized Products