We do everything in-house. That means we control the quality process right from the design stage to packaging the final product; that includes our accessories which go into every one of them. End result is a solution that is truly GRP Industries.

Manufacturing Processes

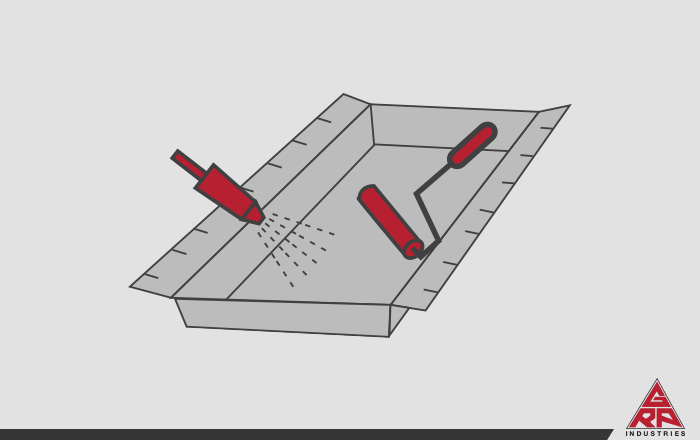

Contact Molding

A pigmented gel coat is first sprayed onto the mold for a high-quality surface. When the gel coat has cured, glass reinforcing mat and/or woven roving is placed on the mold, and the catalyzed resin is poured, brushed or sprayed on. Manual rolling then removes entrapped air, compacts the composite, and thoroughly wets the reinforcement with the resin. Additional layers of mat or woven roving and resin are added for thickness. Reinforcements and accessories are affixed depending on the functionality of the final product and to increase rigidity at points of stress. A catalyst or accelerator initiates curing in the resin system, which hardens the composite without external heat.

Advantages

- Customisation

- Large components

- Cost-effective

- Suited for complex shapes

Limitations

- Longer lead time

- Glossy finish on external surface with rough surface internally

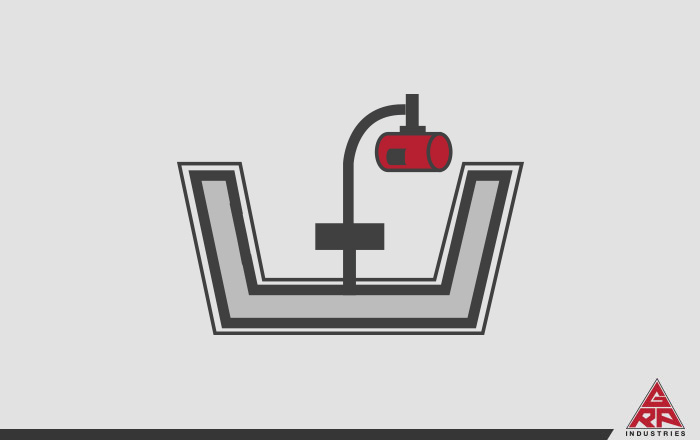

Injection Molding Process

The Injection Molding Process is a closed mold system technique that uses vacuum pressure to drive resin through a laminate. A pigmented gel coat is first sprayed onto the open mold for a high-quality surface. When the gel coat has cured, glass reinforcing mat and/or woven roving is placed on the mold, and the catalyzed resin is poured. Additional layers of mat or woven roving and resin are added for thickness. The mold is closed with a female mold and vacuum pressure is applied to push the resin through the laminate and curing takes place; hardening the composite without external heat.

Advantages

- Lower weight

- Stronger product

- Shorter lead times

- Glossy finish on external surface with smoother internal finish

- Uniform thickness

Limitations

- Limited customization

- Limited to small sizes

- Higher investment in molds

Vacuum Infusion Process

The Vacuum Infusion Process (VIP) is a technique that uses vacuum pressure to drive resin into a laminate. Materials are laid dry into the mold and the vacuum is applied before resin is introduced. Once a complete vacuum is achieved, resin is literally sucked into the laminate via carefully placed tubing. This process is aided by an assortment of supplies and materials. In a typical hand lay-up, reinforcements are laid into a mold and manually wet out using brushes, rollers, or through other means. An improvement on that method is to use a vacuum bag to suck excess resin out of the laminate.

Advantages

- Higher fiber-to-resin ratio

- Stronger product

- Lighter product

- Large components

- Shorter lead time

- Complex shapes

- Uniform thickness

- Increase quality

Limitations

- Higher initial investment

- Limited customization

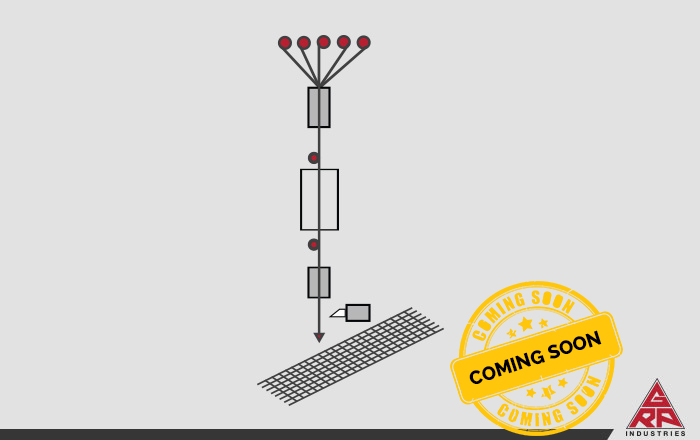

Continuous Sheet Lamination

In Continuous Sheet Lamination Process fiberglass roving reinforcements are set on the shelves and passed on through the resin bank to get wet out after going through a series of guide rollers and bundling grid trays. Roving bundles go into a preformed mold which is set as the required profile of the product requirement. During this process, unwanted bubbles are eliminated before going into the cold mould. Then comes the die where reinforcement materials and resins get cured, pulled out by the draft gear and finally cut into products with different lengths as required. Corrugated sheets are produced by forming shoes which hold the compacted sheet in the required shape during cure. Special surface effects are created by using embossed carrier films that are later removed. Both mat reinforcements and rovings chopped by special wide cutters are employed in the process. Continuous lamination is used to manufacture composite products such as opaque and translucent flat or corrugated panelling and other similar products.

Advantages

- Uniform thickness

- Cost effective

- High throughput rate

- Shorter lead time

Limitations

- Emphasis on large volumes

- Limited customization

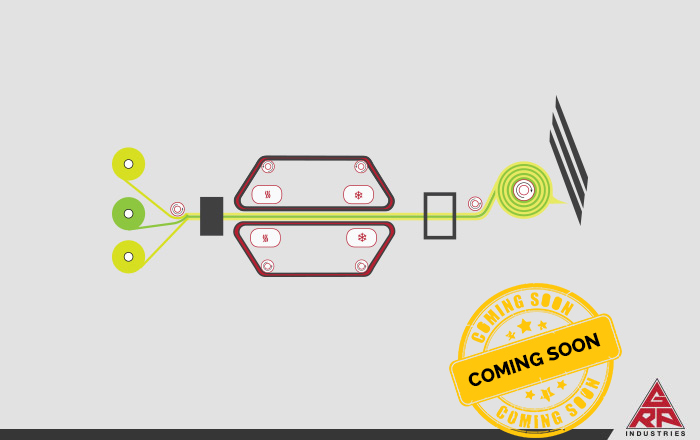

Pultrusion Process

Pultrusion is a manufacturing process for producing continuous lengths of reinforced polymer structural shapes with constant cross-sections. Raw materials are a liquid resin mixture (containing resin, fillers and specialized additives) and flexible textile reinforcing fibers. The process involves pulling these raw materials (rather than pushing, as is the case in extrusion) through a heated steel forming die using a continuous pulling device. The reinforcement materials are in continuous forms such as rolls of fiberglass mat and doffs of fiberglass roving. As the reinforcements are saturated with the resin mixture ("wet-out") in the resin bath and pulled through the die, the gelation, or hardening, of the resin is initiated by the heat from the die and a rigid, cured profile is formed that corresponds to the shape of the die. The hardened composite are deemed as sections that are assembled with other sections to form the final product.

Advantages

- Uniform thickness

- Cost effective

- High throughput rate

- Shorter lead time

- Higher fiber-to-resin ratio

- High Strength

- Low weight

- Customization through assembly of different sections

Limitations

- Emphasis on large volumes

- Non glossy industrial finish

Mold Making

Mold making is also referred to as pattern making and is a skilled trade that incorporates elements of fine woodworking. Pattern makers learn their skills through apprenticeships and trade schools over many years of experience. Although our design engineers help to design the pattern, it is customarily a pattern maker who executes the design. Typical materials used for pattern making are wood, metal or plastics. A pattern is a replica of the final product that needs to be manufactured. The pattern is used to prepare the mold which represents the cavity into which glass fibers and polyester resins are laid for lamination. Often, molds are repeatedly cast from themselves to produce male and female versions until the desired strength and finish of the final mold is achieved. The process however begins with patterns that are made to exacting standards of construction and dimensions.

Metal Fabrication

Our metal fabrication department manufactures the very many metal accessories such as hinges, locks, camshafts, mounting plates etc. that go into each and every one of our products. We recognize the primary function of our products is to provide reliable protection. Thus our accessories are vital to delivering on that promise and fabricated in-house. Metal fabrication is a value added process including welding, cutting, forming, bending and machining. Metal fabrication usually starts with shop drawings including precise measurements then moves to the fabrication stage and finally to the quality testing and installation stage. Our large fabrication department offers greater quality control by limiting the need to locate multiple vendors for different services.

Enclosures

Enclosures Kiosks

Kiosks Battery Enclosures

Battery Enclosures Instrumentation Products

Instrumentation Products Fire and Safety Enclosures

Fire and Safety Enclosures Roofing Systems Products

Roofing Systems Products Utility Approved Enclosures

Utility Approved Enclosures Customized Products

Customized Products