Vacuum infusion technology introduced

GRP Industries has adopted Vacuum infusion and the latest addition to the manufacturing processes. The Vacuum Infusion Process (VIP) is a technique that uses vacuum pressure to drive resin into a laminate. Materials are laid dry into the mold and the vacuum is applied before resin is introduced. Once a complete vacuum is achieved, resin is literally pulled into the laminate via carefully placed tubing. This process is aided by an assortment of supplies and materials. GRP Industries is going to use the Vacuum Infusion process for manufacturing special enclosures and kiosks, leading to higher fiber to resin ratio with high strength and a light weight product. This process is mainly used for large and complex shapes.

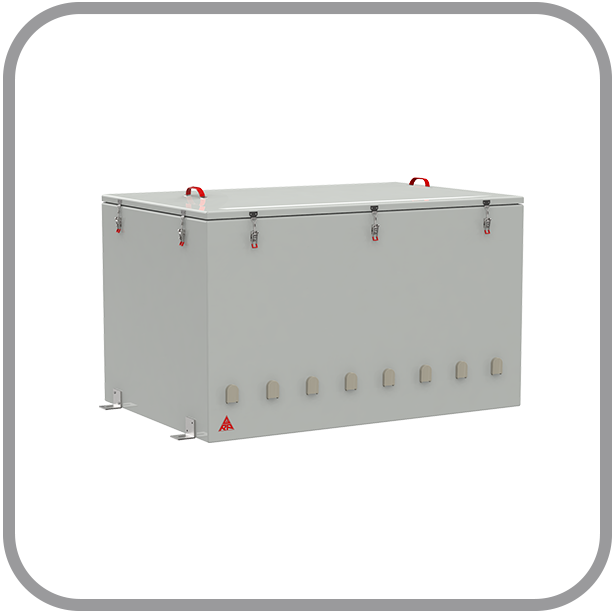

Enclosures

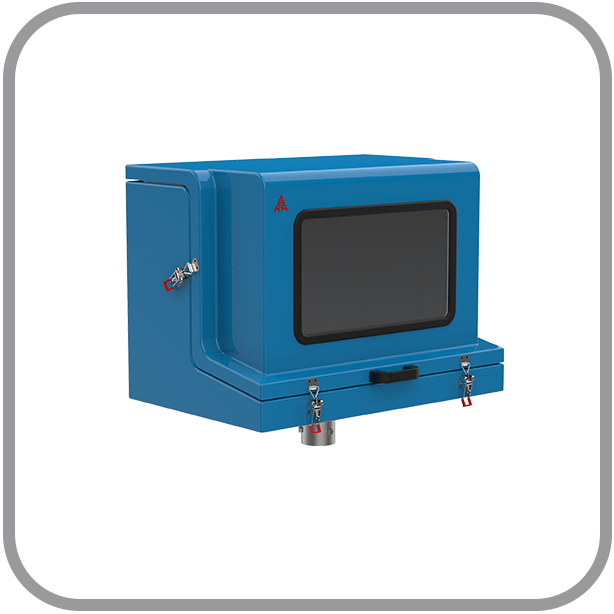

Enclosures Kiosks

Kiosks Battery Enclosures

Battery Enclosures Instrumentation Products

Instrumentation Products Fire and Safety Enclosures

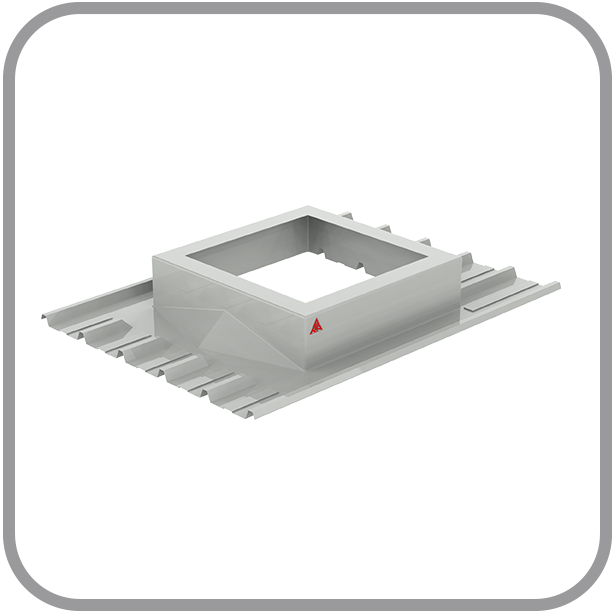

Fire and Safety Enclosures Roofing Systems Products

Roofing Systems Products Utility Approved Enclosures

Utility Approved Enclosures Customized Products

Customized Products